Automation environments continue to evolve toward higher precision, tighter energy control, and greater responsiveness. Traditional motor technologies often struggle to meet these demands without added mechanical complexity or efficiency losses. As a result, many industries are transitioning toward the permanent magnet synchronous motor as a core motion solution.

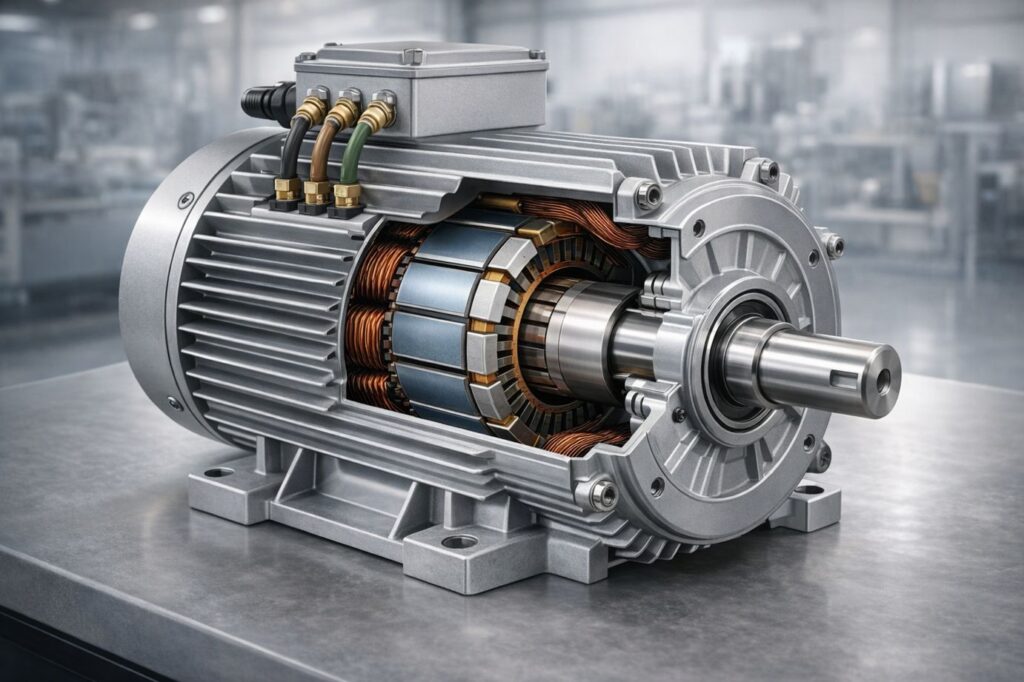

PMSM designs use permanent magnets in the rotor, eliminating the need for rotor current and reducing electrical losses. This allows motors to deliver high torque density, faster response, and improved efficiency across a wide operating range.

For automation systems that depend on accurate speed and position control, these characteristics offer measurable advantages.

Performance Characteristics of Synchronous Motor VFD Setups

PMSM technology relies on precise coordination between the motor and its drive system. In synchronous operation, the motor rotor rotates in exact alignment with the stator’s magnetic field, allowing highly controlled motion.

When paired with a properly configured drive, PMSM systems deliver rapid acceleration and deceleration without sacrificing stability. This makes them well-suited for applications requiring frequent speed changes or tight process control.

A PMSM motor drive provides advanced control algorithms that manage torque, speed, and position with high resolution. These drives continuously adjust output based on feedback, maintaining smooth operation under changing loads.

Another defining characteristic is efficiency at partial loads. Unlike some induction motors, PMSMs maintain high efficiency even when operating below rated speed. This supports energy savings in automation systems that do not run continuously at full output.

Advantages Over Other Motor Types

One of the primary advantages of PMSM technology is higher power density. PMSMs deliver more torque per frame size compared to many conventional motor designs. This allows compact system layouts and reduces the mechanical footprint.

Efficiency is another key benefit. By eliminating rotor losses, permanent magnet synchronous motors convert more electrical energy into usable mechanical output. This reduces heat generation and improves overall system thermal management.

PMSMs also offer superior dynamic response. Faster torque reaction improves accuracy in positioning applications and reduces cycle times in automated processes. This responsiveness supports improved throughput without compromising precision.

Lower maintenance requirements further distinguish PMSMs. With fewer internal losses and reduced thermal stress, components experience less wear over time. This contributes to longer service life and more predictable maintenance schedules.

Key Sectors Using PMSM Motor Drives

PMSM technology has gained traction across several automation-intensive industries. In manufacturing, PMSMs support high-speed packaging, robotics, and CNC machinery where precise motion control is critical.

Material handling systems use PMSMs to improve conveyor control, automated storage, and pick-and-place operations. The ability to manage variable loads efficiently helps maintain smooth operation across complex logistics environments.

Process industries such as food production, pharmaceuticals, and chemical processing benefit from consistent speed regulation and energy efficiency. PMSMs support stable process conditions while minimizing energy waste.

Renewable energy systems and test automation platforms also leverage PMSM designs for their efficiency and controllability, especially where accurate speed synchronization is required.

Conclusion

As automation systems demand greater efficiency and precision, PMSM technology continues to gain adoption across industrial sectors. High torque density, responsive control, and reduced losses make PMSMs a strong fit for advanced motion applications.

By integrating a properly configured synchronous motor VFD, facilities can unlock the full performance potential of PMSM technology while maintaining stable, efficient, and reliable automated operations.