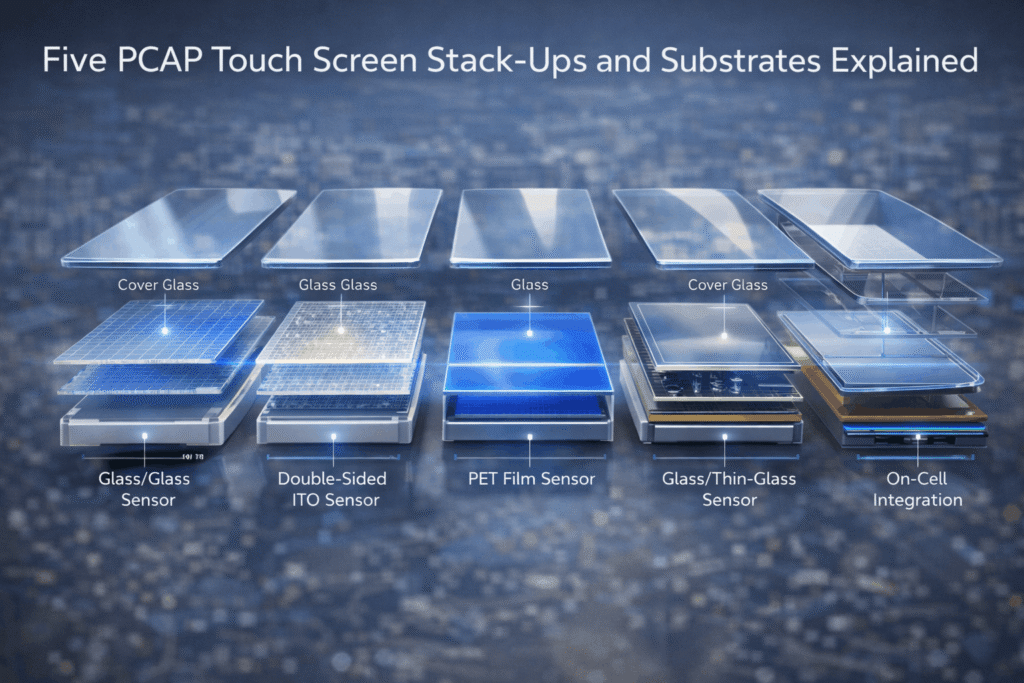

Industrial and commercial devices rely on touch interfaces that deliver accuracy, durability, and long service life. In projected capacitive technology, performance depends heavily on PCAP touchscreen stack-up design and substrate selection. These factors influence optical clarity, mechanical strength, sensitivity, and integration flexibility.

Understanding how common PCAP stackups are built helps OEMs and engineers select the right configurations. These configurations must align with product requirements, environmental conditions, and lifecycle expectations.

What Is a PCAP Touch Screen Stack-Up in Industrial Displays?

A PCAP touch screen stack-up refers to the layered construction of materials that form the touch interface. These layers typically include a cover surface, conductive sensing elements, adhesives or bonding layers, and the interface to the display below.

Each layer contributes to how the touchscreen responds to input, withstands repeated use, and integrates with the overall device enclosure. Stack-up choices directly affect thickness, optical performance, durability, and manufacturing complexity.

Common Substrate Materials Used in PCAP Touch Screens

PCAP touch screens rely on transparent conductive materials to detect touch events. Indium tin oxide (ITO) stands out for its electrical conductivity and optical transparency. The application and layering of ITO define the stack-up type.

1. SITO (Single-layer ITO)

Single-layer ITO places the conductive layer on one side of the substrate.

Key characteristics:

- Simpler construction

- Reduced manufacturing cost

- Suitable for basic touch requirements

SITO stack-ups often support single-touch or limited multi-touch applications. They provide acceptable performance for less demanding interfaces where high-resolution sensing is not critical.

2. DITO (Dual-layer ITO)

Dual-layer ITO uses two conductive layers, typically separated by an insulating layer.

Key characteristics:

- Improved touch resolution

- Better multi-touch capability

- Balanced cost and performance

DITO stack-ups in a PCAP touch panel support more precise gesture detection than SITO designs. Many industrial HMIs use this configuration to achieve reliable multi-touch functionality without excessive thickness.

3. OGS (One Glass Solution)

One glass solution integrates the sensing electrodes directly onto the cover glass.

Key characteristics:

- Reduced total thickness

- Improved optical clarity

- Fewer bonded interfaces

OGS configurations are well-suited for applications that prioritize display readability and compact form factors. Many PCAP touch screen manufacturers recommend using this stack to reduce the number of internal layers. This approach reduces internal reflections and improves visual performance.

4. 2-Layer Film

Two-layer film stack-ups use flexible film substrates with conductive coatings.

Key characteristics:

- Lightweight construction

- Flexible design options

- Lower material cost

Film-based stack-ups in PCAP are suitable for applications where weight reduction and cost control are critical. However, they typically offer lower mechanical durability than glass-based alternatives and may require additional protection.

5. 2-Layer Glass

Two-layer glass stack-ups use glass substrates for both conductive layers.

Key characteristics:

- High structural stability

- Long-term durability

- Consistent touch performance

This configuration supports demanding industrial and medical environments requiring stable touch accuracy over extended operating cycles. Glass-based stack-ups tolerate repeated cleaning and frequent interaction without performance degradation.

Choosing the Right PCAP Stack-Up for Industrial Applications

Selecting the appropriate PCAP stack-up involves balancing performance needs with mechanical and environmental constraints. Important considerations include:

- Required touch resolution and gesture support

- Expected operating environment

- Mechanical strength and surface durability

- Optical clarity and viewing conditions

- Product lifecycle and availability requirements

Early evaluation of stack-up options helps reduce redesign risk and supports predictable manufacturing outcomes. Matching the PCAP touchscreen stackup to the application ensures consistent performance throughout the product’s service life.